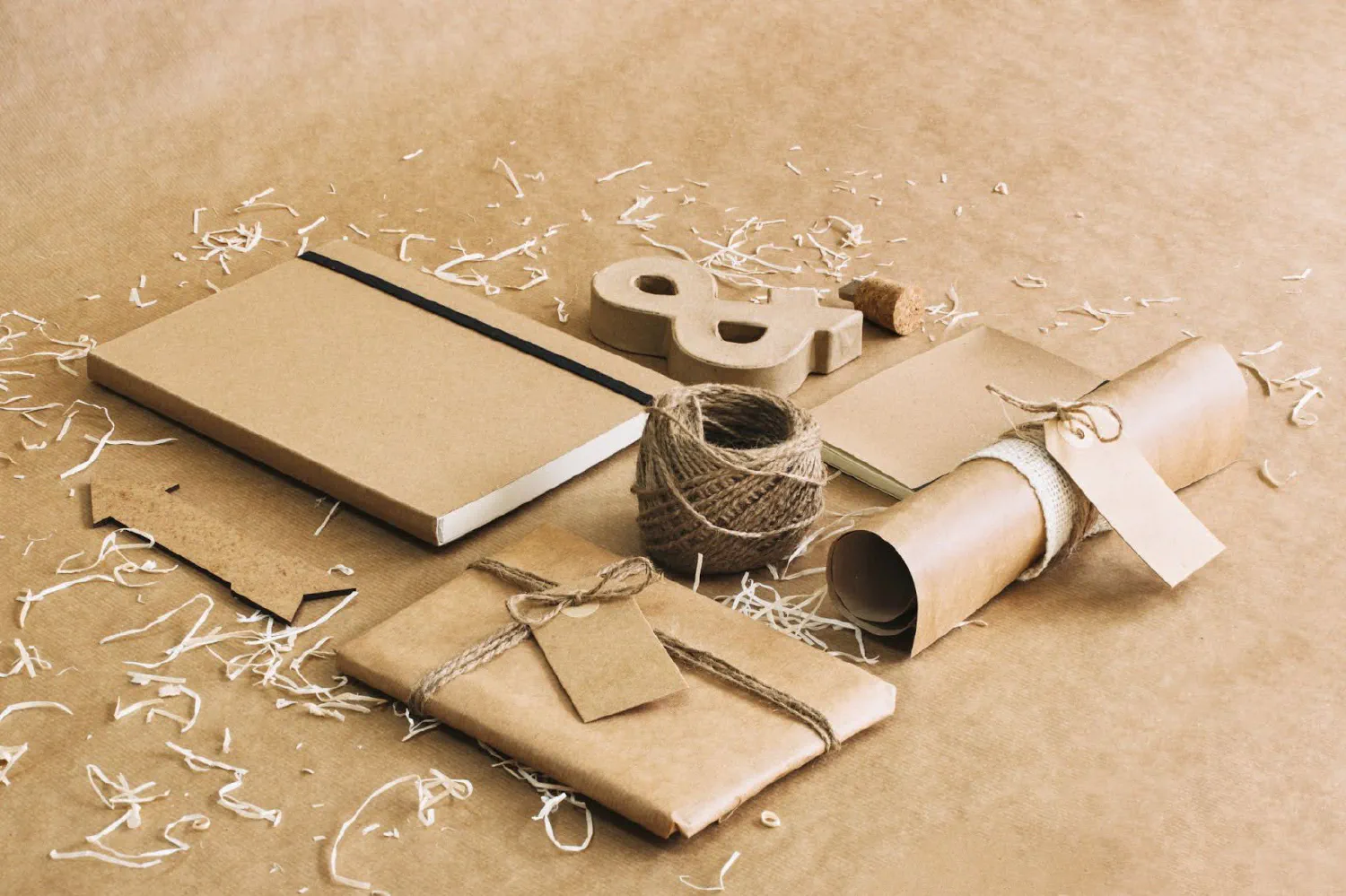

Introduction: Rethinking Packaging for a Sustainable Tomorrow

Every day, millions of packages are produced, shipped, and discarded—contributing to environmental issues like plastic pollution, resource depletion, and excessive waste. Traditional packaging often prioritizes convenience over sustainability, leading to immense landfill waste and carbon emissions.

As global awareness of environmental impact grows, sustainable packaging has become a necessity rather than a choice. Businesses and consumers alike are seeking eco-friendly solutions that reduce waste, conserve resources, and promote a circular economy.

In this blog, we’ll explore 10 cutting-edge sustainable packaging solutions that are revolutionizing the industry—offering hope for a greener, more responsible future.

1. Biodegradable & Compostable Materials

What They Are

Biodegradable and compostable materials break down naturally over time, reducing waste and environmental harm. Biodegradable materials degrade into smaller components, while compostable materials turn into nutrient-rich compost when processed in the right environment.

Impact & Benefits

- Reduces persistent waste—Unlike conventional plastics, these materials don’t linger in the environment.

- Enriches soil—Compostable materials contribute to healthier ecosystems.

Common Uses: Food service ware, packaging films, produce bags

Challenges: Requires specific composting conditions; can contaminate recycling streams if disposed of incorrectly.

2. Recyclable Packaging Solutions

What It Is

Packaging designed for easy recyclability, ensuring materials can be reprocessed instead of ending up in landfills.

Impact & Benefits

- Lower carbon footprint—Reduces virgin material usage.

- Creates a closed-loop system—Supporting circular economy principles.

Common Uses: PET bottles, HDPE containers, paper-based cartons

Challenges: Contamination from adhesives, labels, or food residue; limited recycling infrastructure.

3. Lightweight Packaging

What It Is

Reducing the amount of material used in packaging while maintaining durability.

Impact & Benefits

- Reduces resource extraction—Less plastic, paper, and energy required.

- Lower transportation emissions—Less weight equals reduced shipping costs.

Common Uses: Thin film packaging, optimized carton designs, lightweight bottles

Challenges: Must balance durability vs. reduced material use.

4. Reusable Packaging Systems

What It Is

Packaging designed to be used multiple times, reducing waste through returnable, refillable, or durable materials.

Impact & Benefits

- Significantly reduces landfill waste.

- Resource efficiency—Fewer materials required over time.

Common Uses: Glass milk bottles, refill stations, tote bags

Challenges: Requires behavioral change and logistics infrastructure.

5. Plant-Based Packaging

What It Is

Materials derived from renewable plant sources rather than fossil fuels.

Impact & Benefits

- Minimizes dependence on petroleum plastics.

- Lower carbon footprint—Reduces greenhouse gas emissions.

Common Uses: Sugarcane-based packaging, seaweed films, mushroom packaging

Challenges: Land and water usage concerns; some materials lack biodegradability.

6. Monomaterial Packaging

What It Is

Packaging made from a single type of plastic or material, improving recyclability.

Impact & Benefits

- Easier sorting for recycling facilities.

- Higher-quality recycled output.

Common Uses: Flexible pouches, single-material plastic containers

Challenges: Must match protection levels of multi-layer packaging.

7. Zero-Waste Packaging

What It Is

A philosophy that eliminates landfill waste, ensuring packaging is fully recyclable, reusable, or compostable.

Impact & Benefits

- Avoids disposal issues.

- Supports a circular economy.

Common Uses: Plastic-free packaging, refill systems, compostable wraps

Challenges: Requires systemic changes in supply chains and consumer behavior.

8. Minimalistic Packaging Designs

What It Is

Reducing unnecessary packaging layers, branding, and bulk while keeping functionality intact.

Impact & Benefits

- Less material use—Reduces waste and production costs.

- Appeals to conscious consumers.

Common Uses: Simple cardboard packaging, minimalist labeling

Challenges: Ensuring product protection with fewer materials.

9. Renewable Energy in Packaging Production

What It Is

Factories powering production with solar, wind, hydro, or biogas energy.

Impact & Benefits

- Cuts carbon footprint during manufacturing.

- Aligns with global sustainability goals.

Common Uses: Green-certified factories producing packaging materials

Challenges: Transitioning existing facilities requires investment.

10. Smart Packaging for Sustainability

What It Is

Tech-enhanced packaging that improves environmental transparency and efficiency.

Impact & Benefits

- Guides better recycling behaviors—QR codes, freshness indicators, RFID.

- Optimizes reverse logistics—Efficient reuse tracking.

Common Uses: Interactive labeling, refill tracking, waste reduction programs

Challenges: Technology integration costs for businesses.

Conclusion: The Future of Sustainable Packaging

No single packaging solution can solve the global waste crisis—but combining biodegradable materials, recycling innovations, reuse systems, and smart technology can drive real change. A circular approach is key, where businesses design packaging that flows back into the system rather than ending up in landfills.

Your Role: Whether you’re a consumer or a brand, your choices matter. Support companies investing in sustainable packaging and help push industries toward more responsible solutions.

Ready to make a difference? Explore how your brand can implement sustainable packaging today!